New Kevlar® Paper Enables Ultra-Lightweight Aerostructures

The commercial aerospace industry is one of the most challenging and complex industries in which to operate. Today’s commercial aircraft OEMs and operators must address a complex combination of economic, technical, safety and environmental demands to achieve long-term business success.

Aerostructures represent a key part of this complexity. In addition to meeting precise structural requirements, aerostructures must meet cost, producibility, durability and environmental resistance targets. Interior components must also deliver on strict flammability and heat release regulations.

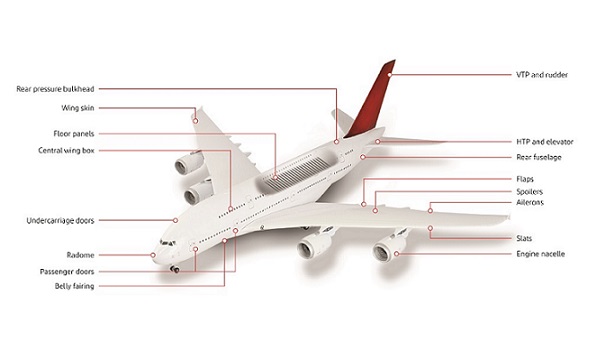

Sandwich-type aerostructures using lightweight honeycomb cores made from DuPont™ Nomex® and Kevlar® aramid papers have been established in the industry for decades. As illustrated below, these structures are deployed extensively throughout the aircraft, from less demanding interior parts to highly demanding exterior structures. Such components are the most structurally efficient known, where necessary mechanical performance is achieved at the lowest possible weight.

Lightweighting provides many benefits. The most obvious is fuel efficiency. Less propulsive force is required to keep a lighter aircraft aloft, which translates into the following benefits:

- Reduced fuel burn and expense

- Increased payload

- Increased range

One additional lightweighting benefit is sustainability. The global aerospace industry produces around 2% of all CO2 emissions (www.iea.org/reports/aviation). Reducing aviation’s environmental footprint is key to a more sustainable industry.

Reduced fuel burn results in reduced operating emissions. With over 99% of CO2 particles emitted during aircraft operation over its entire life cycle, lightweighting is one of the most immediate and accessible routes toward reducing an aircraft’s carbon footprint, accumulating a huge benefit over its 20-30 year operating life.

These benefits are not limited to fuel-based aircraft; new electric advanced air mobility (AAM) / eVTOL aircraft also benefit. One can argue that lightweighting is even more critical for AAMs, because the energy density of batteries is more than an order of magnitude lower than that of liquid hydrocarbons, significantly constraining range and payload (i.e., the number of passengers or cargo). Every pound of weight saved is precious to the AAM business case.

In response to the need for further lightweighting, DuPont has commercialized an ultralight Kevlar® aramid paper product, for use in aircraft cabin interior sandwich structures – especially commercial aircraft and AAMs. With passenger cabin interior accounting for roughly 15% of an aircraft’s weight, lightweighting interior parts contributes directly to reduced fuel consumption while offering lower operating costs, reduced carbon footprint and increased range and/or payload.

Until now, the lightest-weight commercially available honeycomb cores have been using Nomex® Type 412 paper product with a nominal thickness of 1.5 mil (38μm) and an areal weight of 28 gsm. DuPont’s new ultra-lightweight Kevlar® paper has a nominal thickness of 1 mil (0.001” / 25 μm) and an areal weight of 18 gsm, resulting in a 30% core weight reduction (from 29 kg/m3 to 20 kg/m3 core density) while delivering comparable mechanical, flammability and environmental performance of the intended application.

Employing cutting-edge composite materials often comes at a steep cost because such materials are early in their life cycle and produced at low rates, however DuPont’s Kevlar® N636 1 mil paper is produced at existing commercial facilities as the other N636 grades. Importantly, no significant change to the part manufacturing process should be required.

Ultralight 5 kg Sidewall Demonstrator

A recent project between DuPont and Germany’s Composites Technology Center GmbH (CTC, an Airbus Company) and Euro-Composites® S.A, a global aerospace honeycomb manufacturer, proves the benefits of Kevlar® N636 1 mil paper.

The project’s main goal was to reduce overall weight in a typical twin-aisle aircraft sidewall panel. A sidewall is typically made from honeycomb core with laminates of phenolic/glass prepregs on each side, and a decorative foil on the panel’s visible surface.

For this project, ultra-lightweight 20 kg/m3 honeycomb core using Kevlar® N636 1 mil paper replaced the standard 29 kg/m3 honeycomb core using Nomex® T412 1.5 mil paper. The core replacement alone saves 5% of the finished part weight. With innovative and lighter material replacement for other constituents, the part is 24% lighter with mechanical, flammability and environmental performances comparable to current parts.

In addition to these meaningful weight savings, not only the implementation costs at manufacturing site are scaled down as the process remains unchanged, but significant labour costs associated with part preparation are reduced: full-scale sidewall parts made from Kevlar® N636 1 mil paper exhibit greatly reduced honeycomb pattern print-through, allowing minimal manual surface preparation before the decorative foil application.

Conclusion

DuPont is the largest aramid paper provider for honeycombs used for secondary and interior aircraft structures, helping the industry to meet its lightweighting needs for over 50 years. DuPont’s new Kevlar® N636 1 mil paper offers aerospace customers a new, affordable and easy to implement solution to make honeycomb core panels that are 20+% lighter. This provides lower aircraft operating cost, increased range or payload while at the same time reducing an aircraft’s carbon footprint.

Click here to read more.